Diaphragm walls are very rigid walls that offer significant resistance to bending from lateral loads and are water-resistant.

Common uses

Process

Since reinforced walls are designed and constructed as a series of panels, their overall length has no practical limit. Individual panels usually range in sizes between 15 to 30 feet in length, with standard widths ranging between 24, 30, 36, and 48 inches. The depths of the wall have exceeded 200 feet regularly. Depending on the purpose of the wall, possible shapes of walls include right angles, polygonal, T-shaped, and cross-shaped walls.

Equipment used

Clam Shells (Cable Grabs)

This equipment is suitable for soft, medium dense to dense soil & boulders (in combination with chisels) to suggested depths of up to 120ft (37m).

Hydraulic Clam Shells (Hydraulic Grabs)

This equipment is suitable for hard soil and stiff clays to suggested depths of up to 260ft (80m).

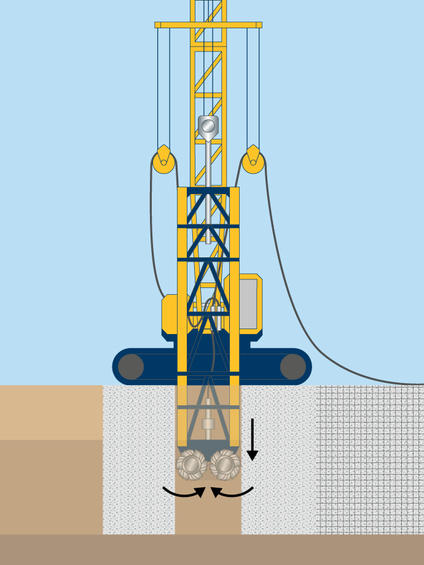

Hydromills (Cutters)

This equipment is suitable for nearly all soils and rock types. Hydromills can use different cutting wheels depending on the soil and rock conditions. Achieving large depths is possible (>500ft (150m)) while maintaining very accurate verticality (<.3%), which is essential for proper closure at depths of hundreds of feet.

Applying the hydromill technique for the construction of large projects with deep slurry walls and cut-off walls offers the following advantages over the conventional clamshell techniques: economy, output, reliability, and environmental compatibility.

The hydromill continuously removes soil from the bottom of the trench, breaks it up, and mixes it with the bentonite slurry in the trench. The slurry, heavy with soil particles, is pumped through pipes to the desanding plant, where it is cleaned and returned to the trench.

Specialist contacts

- T:

- 973-400-3631

Paul is responsible for the strategic pursuit of new underground construction work largely in tunneling, dam construction and rehabilitation, and CCR stabilization. Previously Senior Vice President and Chief Engineer of Moretrench American Corporation, a nationally renowned specialty geotechnical contractor. Responsible for the technical oversight of the company’s soil stabilization, grouting, ground freezing, groundwater control and environmental remediation. Extensive experience with emergency response for geotechnical “failures” related to groundwater and forensic investigation of deep excavation and tunneling ground loss events. Co-author of the third edition of Construction Dewatering and Groundwater Control, published in 2007.

Advantages

Quality assurance

Keller has a fleet of specialist wall excavation and construction equipment to complete all types of diaphragm walls.